The Need for a New Approach

Cost optimization in 2025 is no longer just about reducing expenses—it has become a strategic necessity for business resilience and long-term success. Geopolitical instability, technological advancements and evolving regulatory frameworks are fundamentally altering the cost structures that organizations have relied on for decades.

In this rapidly changing environment, traditional cost-cutting measures such as renegotiating vendor contracts or reducing headcount are important but not sufficient. Instead, companies must adopt a more dynamic, intelligence-driven approach that integrates cost efficiency with business transformation and innovation.

For CxOs, transformation leaders, finance and IT professionals the challenge lies in striking the right balance between reducing costs and maintaining agility, resilience and long-term competitiveness. Concurrently, sourcing and procurement specialists should recognize that the game has changed and that they need to adopt a radically different playbook to remain relevant. Organizations that fail to modernize their cost strategies risk falling behind in an increasingly digital and automated world.

The AI Revolution: Opportunity and Challenge

Artificial intelligence (AI) is rapidly becoming the most disruptive force in cost optimization. When implemented effectively, AI has the potential to reduce operational expenses, increase productivity and automate previously labor-intensive tasks. AI-driven automation and predictive analytics can optimize business processes in ways that were not possible before, enabling organizations to cut costs while maintaining or even enhancing their operational capabilities.

In one example, JPMorgan Chase developed an AI-powered contract analysis platform called COIN, which reviews legal documents in seconds—work that previously took thousands of hours of manual effort. This showcases how AI not only reduces costs but also improves efficiency and accuracy. Similar levels of transformation are rapidly occurring around coding, risk analysis, financial analysis, quality assurance, core operations, customer care and virtually every other area of business.

The power of AI to drive cost optimization continues to grow rapidly. On February 18, xAI introduced Grok 3, an advanced AI model that has set new benchmarks in math, science and coding, surpassing competitors like GPT-4.0, Claude and DeepSeek. It can, among other things, offer detailed insights into cost structures, automate complex decision-making algorithms and enhance scenario modeling for optimizing supply chain logistics, enhancing marketing strategies or improving financial forecasting. From a cost optimization perspective, this dramatically shifts the discussion from “what is the price we are paying for things, and how can we improve that?” to “how are we eliminating things that we used to do and purchase, and replacing them with more efficient, more effective and lower-cost alternatives, (if an alternative is still even required)?”

Of course, AI adoption comes with its own set of financial and strategic challenges. The initial investment in AI infrastructure, software and employee training can be substantial. Moreover, the shortage of skilled AI professionals has driven up the cost of hiring and retaining top talent. Ethical considerations and regulatory compliance also add layers of complexity (and these rules are evolving), requiring businesses to allocate additional resources to governance and risk management. Companies that do not master AI will rapidly fall behind and become non-competitive in both cost and capability.

At the same time, AI is also changing the calculus of globalization. As AI enables more work to be done with fewer human resources, the traditional benefits of offshoring may diminish, leading many enterprises to evaluate more diversified right-shore strategies. The new arbitrage is less about hourly labor costs and more about AI proficiency, and here the investments that IT and BPO managed services providers have made in AI and domain and capability is likely to drive an increasing percentage of cost improvement to their customers.

Please fill out this form to continue.

Regulatory Disruptions: A Source of Savings or Additional Costs?

In the first months of 2025, the U.S. has generated headlines for launching a substantial wave of deregulation and bureaucracy reduction under the newly formed Department of Government Efficiency (DOGE). Regulatory changes in 2025 present generational opportunities for cost savings. In the U.S., the National Association of Manufacturers estimated the per-employee cost of regulatory compliance in 2023 to be $12,800, amounting to a total economic impact of $3.1 trillion. If successful, companies could see substantial cost reductions by eliminating outdated compliance processes and redundant administrative burdens. At the same time, companies may see increased costs as well as new pricing pressures as a result of an aggressive U.S. tariff strategy.

Concurrently, in Europe, the Digital Markets Act (DMA) purports to create fairer digital competition while imposing compliance requirements that could either reduce operational barriers or add regulatory burdens. Companies that proactively adjust to these changes may reap significant cost benefits, while those that fail to adapt could face increased financial and legal risks. The key to success will be anticipating regulatory shifts and integrating them into broader cost optimization strategies. No doubt, those companies that are most successful in navigating these dynamic changes will heavily leverage AI tools in doing so!

The Changing Global Supply Chain: From Cost Efficiency to Resilience

A further complexity is the increased risk associated with global supply chains. The traditional low-cost global sourcing model is under strain. Geopolitical conflicts, cyber threats and increasing economic protectionism are forcing companies to rethink their supply chains, incorporating greater levels of redundancy and agility over traditional consolidation strategies. State-sponsored hacking, industrial espionage, piracy and shifting tariffs are compounding these challenges, increasing the need for enterprises to develop more resilient operational strategies.

An acceleration of AI-powered automation is reducing reliance on low-cost offshore labor, making domestic or nearshore manufacturing strategies more attractive. Apple, for instance, has been diversifying its supply chain by shifting manufacturing from China to India and Vietnam to mitigate geopolitical risks and enhance supply chain resilience. In the U.S., there is a strong political imperative to bring back manufacturing capacity on shore, from both an economic and a security posture. This trend underscores that cost optimization is no longer just about finding the cheapest production sources—it’s about striking a balance between cost efficiency, security and operational stability.

A New Framework for Cost Optimization: Moving Beyond Traditional Cost-Cutting Strategies

All this amounts to a profound reimagining of cost optimization from older approaches. Historically, companies have approached cost optimization as a set of discrete, short-term measures aimed at reducing spending in specific areas. However, in our current economic and technological environment, this fragmented approach has frequently resulted in higher total cost of ownership (TCO) because it fails to account for the interdependencies between business functions and the full technology stack.

A more effective approach involves taking a holistic view of cost management, integrating operational efficiency with long-term business transformation. Microsoft, for example, has been leveraging cloud-based analytics to optimize energy consumption in its data centers, significantly reducing operational costs while enhancing sustainability.

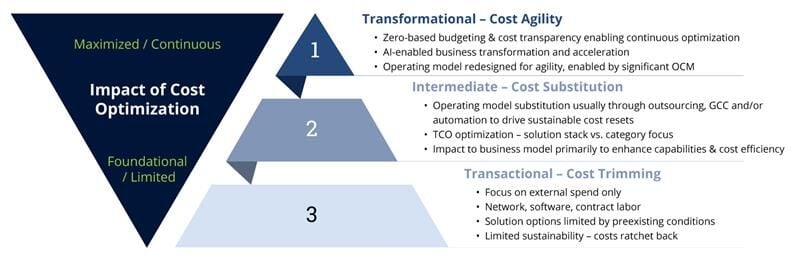

To increase the impact of cost optimization, leaders need to move up the cost optimization pyramid illustrated below. This includes increasingly using automation and better analytical models for more foundational cost trimming and – in addition – employing the principles of cost substitution and cost agility that create a cycle of continuous optimization. See Figure 1.

Cost Optimization: The Big Picture

Leveraging Enterprise Intelligence for Cost Optimization

In 2025, cost optimization will increasingly rely on real-time data, AI-driven insights and advanced financial modeling. Companies that adopt automated cost modeling and AI-powered decision-making will be better positioned to anticipate market fluctuations and adjust their spending accordingly.

For example, Unilever has successfully used AI-powered demand forecasting to optimize inventory management, reducing food waste and improving supply chain efficiency. This illustrates how data-driven decision-making can drive cost efficiencies while supporting sustainability goals.

The Role of Strategic Partnerships in Cost Optimization

Cost transformation is a complex process. We have observed many businesses struggle in achieving results because internal teams continue to attempt to execute using obsolete playbooks. Many organizations achieve faster and more sustainable cost optimization by collaborating with external partners that bring insights and capabilities from experience across multiple organizations, along with significant investments in AI. Transformational sourcing—where companies engage service providers based on outcome-based pricing models—can be an effective way to drive long-term efficiency.

AI-powered managed services incorporate automation and analytics-driven capabilities that allow businesses to more rapidly shed routine functions, freeing up internal resources and providing better business intelligence for more strategic activities. Additionally, forming alliances with technology vendors, consulting firms and data providers can help organizations develop more sophisticated cost models and gain access to the latest innovations in cost management.

A prime example is Tesla, which has redefined cost optimization in manufacturing through strategic supplier partnerships and vertical integration, significantly reducing battery production costs. This demonstrates how cost efficiency can be achieved through innovation and strategic alliances.

The Future of Cost Optimization

The business environment in 2025 demands a fundamentally different approach to cost optimization. Organizations can no longer rely on traditional cost-cutting measures; they must adopt proactive, AI-driven strategies that integrate cost efficiency with long-term transformation.

To succeed in this new landscape, companies must embrace data-driven decision-making, invest in AI and break down silos between departments to take a more holistic approach to cost optimization. The ability to anticipate regulatory, geopolitical and technological shifts will be critical in identifying opportunities for savings while mitigating emerging risks.

For IT leaders, procurement professionals and transformation managers, the time to act is now. Cost optimization is no longer just about reducing expenses—it is about building a more agile, intelligent and competitive organization. By rethinking your business and operating models, analytical frameworks, leveraging AI and engaging with the right strategic partners, businesses can turn cost optimization into a driver of innovation and long-term success.

Are you ready to optimize costs for the future? Discover how ISG can help you build strategic plans for AI, sourcing and next-generation cost models that will transform your business. Contact us to explore tailored cost optimization solutions.