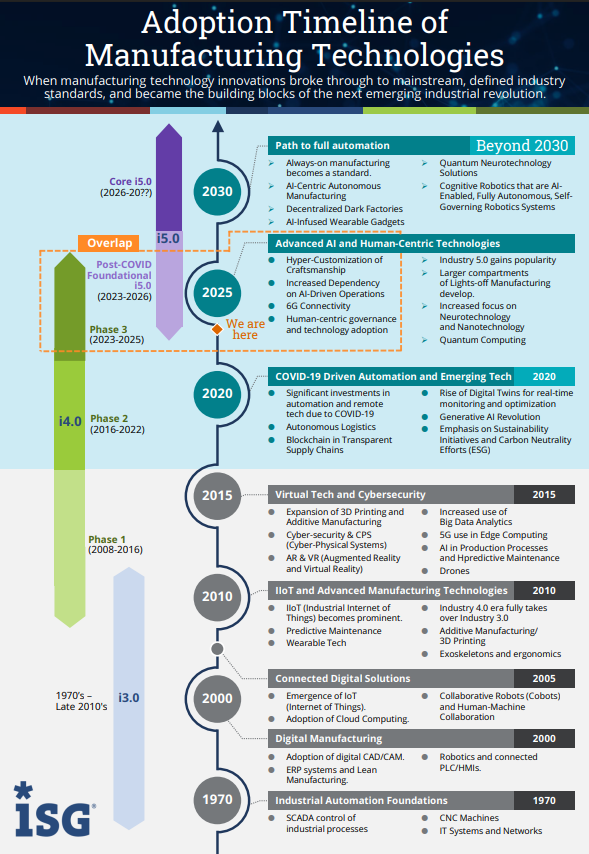

Technology has always defined manufacturing. If we look closely, we will see that important change happens not only when manufacturing technologies are invented but when they are integrated into mainstream manufacturing. Since 1970, we’ve seen three industrial revolutions in manufacturing technology: Industry 3.0, 4.0 and 5.0.

The Manufacturing Timeline

Let’s take a look at the three phases and how they impact the manufacturing industry.

Industry 3.0

From the 1970s to late 2010s, Industry 3.0 established foundational technologies like industrial automation and early IoT, which laid the groundwork for more advanced capabilities.

Industry 4.0

There are three phases in Industry 4.0. The first phase was 2008-2016 and characterized by the rise of cyber-physical systems, virtual tech, AR/VR and the early spread of 5G.

The second phase spanned 2016-2022, when automation was adopted more rapidly through emerging technologies, driven by factors such as COVID-19, blockchain and remote tech solutions. This phase is also notable for the generative AI revolution in 2022, which began reshaping industrial practices around the world. Sustainability also became an industry-wide priority, with global initiatives targeting carbon footprint reductions and aiming for net-zero manufacturing.

The third phase of Industry 4.0 – where we are now – spans 2023-2025. This is defined by human-centric technology like cobots and the fact that advanced AI-driven operations are becoming prolific. Innovations like generative AI are now applied across coding, infrastructure, cybersecurity, PDF data extraction and processing and in many other manufacturing-related operations. This phase is marked by an increased reliance on GenAI, which will need further work with governance and regulation, and “post-COVID foundational” Industry 5.0 thinking, which emphasizes human-technology collaboration.

Read the full 2024 State of the Generative AI Market Report.

Industry 5.0 Overlap

There is an ongoing debate between industry thought leaders about whether Industry 5.0 has begun or not. ISG Research shows that Industry 5.0 is not a clean break from 4.0, but rather a progression where innovation finds increasing relevance through human-centered applications. This overlap reflects how both perspectives are correct. Industry 4.0 is still maturing, while the foundational elements of Industry 5.0 are being established.

Read more about Industry 5.0 characteristics here.

We anticipate that core Industry 5.0 will begin in earnest in 2026 and usher in a three-year period of AI-centric, autonomous, always-on manufacturing. This phase will ultimately pave the way for the evolution of fully autonomous factories, known as dark factories, and cognitive robots (AI-enabled, fully autonomous, self-governing robotic systems) that push manufacturing into hands-off environments that help eliminate human safety incidents.

This era will redefine the relationship between technology and human workers, focusing largely on the automation that complements human expertise instead of replacing it.

How Can ISG Help you?

ISG specializes in helping businesses adopt new technologies such as Industrial IoT (IIoT), generative AI, and digital twins. With our expert consulting services, we provide tailored strategies with a robust vendor sourcing approach. We guide your organization through the complexities of Industry 4.0/5.0 governance, digital transformation and sustainable practices, ensuring you stay ahead of the competition.